Chingwe chophatikizika Chitsulo Chopangira Granulating cha Siliva Wagolide

Magawo aukadaulo

| Chitsanzo No. | HS-GS2 | HS-GS3 | HS-GS4 | Mtengo wa HS-GS5 | Mtengo wa HS-GS6 | HS-GS8 |

| Voteji | 220V, 50/60Hz, Single gawo / 380V, 50/60Hz, 3 Phase | |||||

| Mphamvu | 8kw pa | 10KW | 15KW | |||

| Max Temp | 1500°C | |||||

| Mphamvu (Golide) | 2kg pa | 3kg pa | 4kg pa | 5kg pa | 6kg pa | 8kg pa |

| Nthawi Yosungunuka | 2-3 min. | 3-5 min. | ||||

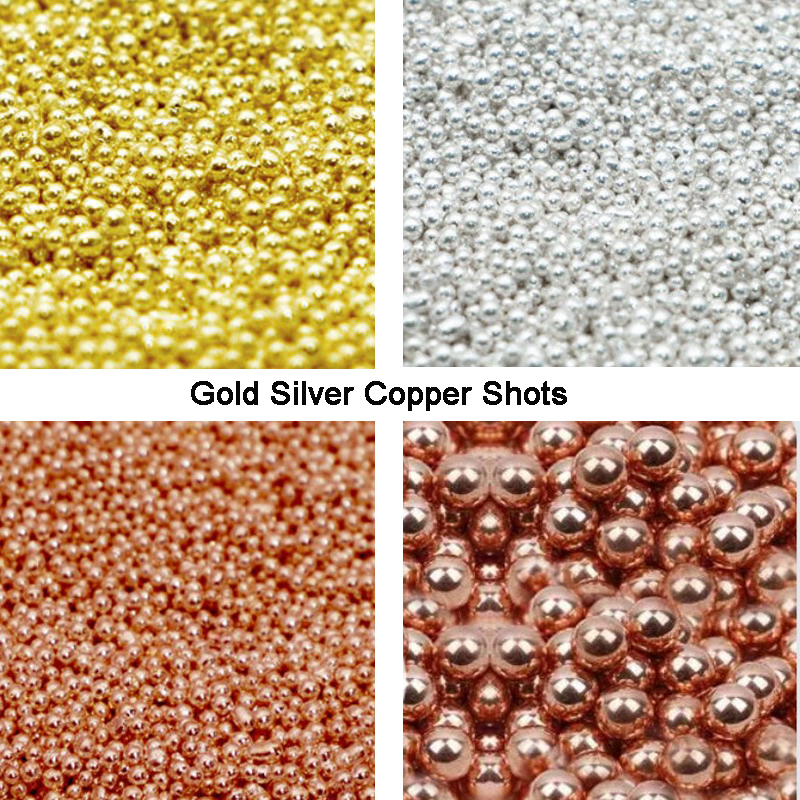

| Kugwiritsa ntchito | Golide, K golide, siliva, mkuwa ndi ma aloyi ena | |||||

| Kupereka mpweya | Mpweya wa compressor | |||||

| Kulondola Kwanyengo | ±1°C | |||||

| Temp detector | Thermocouple | |||||

| Mtundu wozizira | Madzi ozizira (ogulitsidwa mosiyana) kapena Madzi othamanga | |||||

| Makulidwe | 1100*930*1240mm | |||||

| Kulemera | Pafupifupi. 180kg | Pafupifupi. 200kg | ||||

Chiwonetsero cha Zamalonda

Mutu: Ntchito ya chitsulo chopangira zitsulo poyenga golide

Kuyenga golide ndi njira yosamalitsa yomwe imaphatikizapo magawo angapo ndi zida zochotsera golide woyengedwa m'malo ake osaphika. Chimodzi mwa zida zofunika kwambiri pakuyenga uku ndi granulator yachitsulo. Mubulogu iyi, tiwona momwe chitsulo chimagwirira ntchito pakuyenga golide komanso momwe chimathandizira potulutsa golide weniweni.

Kodi granulator yachitsulo ndi chiyani?

Tisanalowe m'gulu la chitsulo choyenga golide, choyamba tiyeni timvetsetse chomwe chitsulo chopangira chitsulo ndi momwe chimagwirira ntchito. Granulator yachitsulo ndi makina opangidwa kuti aphwanye zidutswa zachitsulo kukhala tinthu tating'onoting'ono tating'onoting'ono tating'ono tating'onoting'ono kapena ma granules. Nthawi zambiri amagwiritsidwa ntchito m'mafakitale obwezeretsanso ndi kuwongolera zinyalala pokonza zitsulo zotsalira ndikuzisintha kukhala mawonekedwe owongolera kuti apitilize kukonzanso.

Ntchito ya granulator yachitsulo pakuyenga golide

Pakuyenga golide, granulator yachitsulo imagwira ntchito yofunika kwambiri poyambira pokonza zinthu. Nawa zomwe amathandizira pakuyenga konse:

1. Kuchepetsa zitsulo zachitsulo

Panthawi yoyenga golide, mitundu yosiyanasiyana ya zinyalala zachitsulo imapangidwa, kuphatikizapo zida zowonongeka, zinyalala zamagetsi ndi zinthu zina zokhala ndi zitsulo. Zidazi zimafuna kuchepetsa kukula kuti zithandizire kukonza zina. Apa ndipamene ma granulators achitsulo amayamba kugwira ntchito. Imaphwanya bwino ndi kuphwanya zitsulo za pellets, ndikupanga chakudya chokhazikika kuti chiziyeretsedwe.

2. Kulekanitsa zinthu zopanda golide

Chitsulo chachitsulo chikapangidwa ndi granulated, sitepe yotsatira mu ndondomeko yoyenga golidi ndiyo kulekanitsa zinthu zopanda golidi ku zigawo zomwe zili ndi golidi. Chitsulo cha granular chimadutsa njira zina zolekanitsa monga kupatukana kwa maginito ndi kulekanitsa kochokera ku kachulukidwe kuti tilekanitse zinthu zomwe zili ndi golide ndi zinyalala zonse zazitsulo. Kukula kwa yunifolomu ndi mawonekedwe a zitsulo za granular zimathandizira njira zolekanitsa izi, zomwe zimapangitsa kuti ntchitoyi ikhale yabwino.

3. Sinthani malo opangira mankhwala

Zinthu zomwe sizinali golide zitapatulidwa, zigawo zomwe zimakhala ndi golide wa granular zimakonzedwa ndi mankhwala kuti zichotse golide woyenga. Mtundu wa tinthu tating'onoting'ono umapereka malo okulirapo, kulola kuti mankhwala alowe ndikuchitapo kanthu ndi tinthu tagolide bwino. Izi zimapangitsa kuti m'zigawo zikhale bwino kwambiri komanso njira yoyenga bwino kwambiri.

4. Kupititsa patsogolo njira zosungunulira ndi zoponyera

Golidiyo akatulutsidwa kuchokera kuzinthu zong'ambika, amakonzedwanso kudzera mu kusungunuka ndi kuponyedwa kuti apange golide kapena mawonekedwe ena ofunikira. Mtundu wa granular wa golide umathandizira kusungunuka chifukwa umatenthetsa ndikusungunula zinthu mofanana. Izi zimapanga zinthu zagolide zapamwamba zokhala ndi chiyero chokhazikika.

Ponseponse, ma granulator achitsulo amagwira ntchito yofunika kwambiri poyambira kuyenga golide pokonzekera zopangira kuti zipitirire kukonzanso, kulimbikitsa kulekanitsa bwino kwa zinthu zomwe si zagolide, kukulitsa malo opangira mankhwala, ndikuwongolera njira zosungunulira ndi zoponya.

Kufunika kwa njira zoyenga bwino za golidi

Njira yoyenga bwino ya golide ndiyofunikira pakuwonetsetsa chiyero ndi mtundu wa chinthu chomaliza cha golide. Kaya amagwiritsiridwa ntchito kupanga zodzikongoletsera, zopangira ndalama, kapena kupangira mafakitale, golide weniweni ndi wamtengo wapatali ndipo amafunidwa. Choncho, ntchito ya zipangizo monga zitsulo zopangira zitsulo poyenga golide ku chiyero ndi khalidwe lofunika silingathe kupitirira.

Kuphatikiza pa luso laukadaulo, njira yoyenga bwino ya golide imathandizanso kuti chilengedwe chikhale chokhazikika. Poyang'anira bwino ndi kukonza zinyalala zazitsulo, kuphatikizapo zinyalala zamagetsi ndi zida zowonongeka, makampani oyenga amatha kuchepetsa kuwonongeka kwa chilengedwe cha migodi ya golide ndikuthandizira kuti pakhale kayendetsedwe kazinthu zokhazikika.

Pomaliza

Mwachidule, ma granulator achitsulo amagwira ntchito yofunika kwambiri pakuyenga golide, kuphatikiza kukonza zopangira, kuthandizira kulekanitsa bwino, kupititsa patsogolo mankhwala opangira mankhwala, komanso kukonza njira zosungunulira ndi zoponya. Kuthandizira kwake pakuchita bwino kwanthawi zonse komanso kuwongolera kwagolide sikunganyalanyazidwe. Pamene kufunikira kwa golide woyenga kukukulirakulira, njira zoyenga bwino, zothandizidwa ndi zida zapamwamba monga ma granulator achitsulo, zikukhala zofunika kwambiri kuti zikwaniritse zofunikira zamakampani pazogulitsa zagolide wapamwamba kwambiri.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur