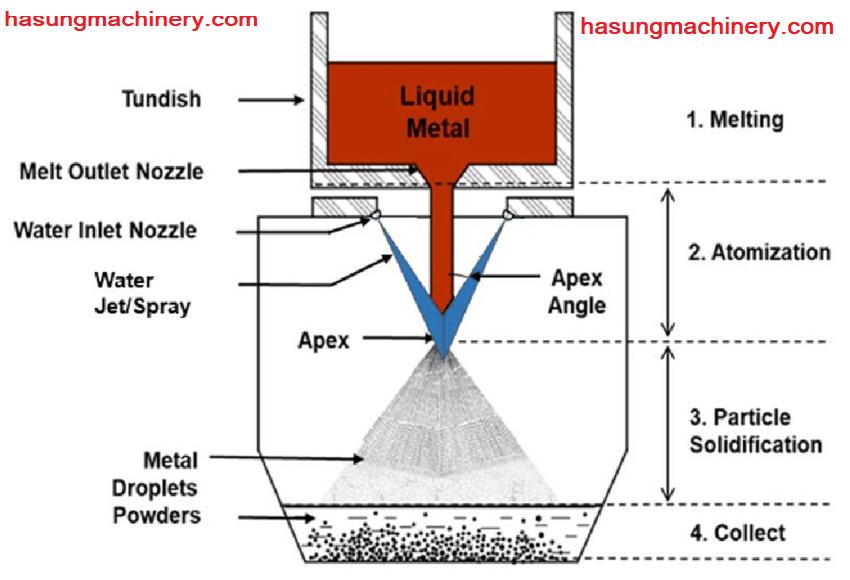

Zidazi zimagwiritsidwa ntchito makamaka popanga ufa wachitsulo kapena granule mu atomization. chipinda ndi high pressure water atomization njira pambuyo zitsulo kapena zitsulo aloyi. zisungunuke pansi pa malo otetezedwa ndi mpweya kapena mpweya wamba. Mtengo wogwiritsira ntchito makina ndi mtengo wopanga ufa ndi wotsika. Metal Powder Water Atomization Equipment ndi njira yokonzekera ufa pomwe chitsulo kapena madzimadzi ophatikizika amathyoledwa kukhala mikanda yaying'ono ndi madzi ofulumira (atomization medium) kapena njira zina, zotsatiridwa ndi kuchulukana kukhala ufa wamphamvu. Chilichonse chomwe chingapange madzimadzi chikhoza kukhala atomu ndi ufa. Kuthamanga kwakukulumadzi atomizationNjira imatha kupanga ndalama komanso moyenera kupanga MIM zitsulo amalgam ufa, ufa wapadera wachitsulo, ufa wachitsulo wofulumira, ufa wamtengo wapatali wachitsulo, ufa wopangidwa ndi mkuwa, ndi ufa wapamwamba kwambiri, ndi zina zotero. Zomwe zimagwiritsidwa ntchito kwambiri ndi zida zamagetsi zamagetsi ndi zida zamagetsi zamagetsi. Panthawi yoperekera ufa wa atomization, sungunulani zitsulo zosayengedwa kuti zikhale zoyenerera amalgam fluid (zotentha kwambiri pa 100-150 ℃) ndi chotenthetsera chamagetsi kapena choyatsira cholandirira, kenako ndikulowetsa mu tundish pamwamba pa spout ya atomiki. Timadzi timene timatulutsa timadzi timene timatulutsa timadzi timene timatulutsa m'munsi mwa tundish, ndipo tikamadutsa m'mphuno, amapangidwa ndi mikanda yabwino kwambiri akakumana ndi mphepo yamkuntho kapena madzi. Madontho a atomu amawumitsidwa mwachangu kukhala ufa wophatikizika muchipinda chotsekedwa cha atomizing. Mwambiri, tinthu tating'ono ta mpweya wa atomized ufa ndi wozungulira, wokhala ndi okosijeni wochepera (pansi pa 100 × 10), ndipo amatha kupangidwa molunjika kukhala zinthu zolimba ndi luso la thermoforming, (mwachitsanzo, kufinya kwa isostatic). Tinthu tating'onoting'ono ta madzi a atomu ndi mawonekedwe osadziwika bwino okhala ndi okosijeni wambiri (pamwamba pa 600 × 10) ndipo amayenera kupsya mtima. Imakhala ndi kupsinjika kwakukulu ndipo imatha kufinyidwa mu magawo amakina.

Mfundo yogwira ntchito

Njira yoperekera ufa wachitsulo pogwiritsa ntchito ma atomization amadzi opopera zida ndi mbiri yakale. Kale, anthu ankathira chitsulo chamadzimadzi m'madzi n'kuching'ambika m'zitsulo zabwino kwambiri, zomwe zinkagwiritsidwa ntchito ngati zitsulo zosayeretsedwa; mpaka pano, pali anthu amene amathira madzi otsogolera mwachindunji m'madzi kuti apange kuwombera. Njira yopunthira ma atomization yamadzi imagwiritsidwa ntchito popanga ufa wowuma. Njira yoyendetsera ndi yofanana ndi yomwe yatchulidwa kale yomwe imalola madzi kuphulitsa zitsulo zamadzimadzi, komabe zokolola zowononga zakhala zikuyenda bwino kwambiri. Kuti apange ufa wophatikizika ndi giya yopondera yamadzi, golide wowoneka bwino amayenera kusungunuka mu chotenthetsera kaye, ndipo golide wamadzimadziyo ayenera kutenthedwa kwambiri pafupifupi madigiri 50. Kenako, analowetsedwa mu tundish. Yambitsani siphon yamadzi yothamanga kwambiri isanalowe madzimadzi agolide, ndipo lolani chida champhamvu kwambiri chamadzi kuti chiyambe ntchitoyo. Madzi a golide omwe ali mu tundish amadutsa mu bar ndikulowa mu atomizer kudzera mu spout yotayira kumunsi kwa mtolo. Atomizer ndiye chida chofunikira kwambiri popereka ufa wagolide wokhala ndi chifunga chamadzi chambiri. Chikhalidwe cha atomizer chimadziwika ndi luso lowononga la ufa wachitsulo. Pansi pa ntchito yamadzi othamanga kwambiri kuchokera ku atomizer, madzimadzi a golide nthawi zonse amathyoledwa kukhala mikanda yabwino, yomwe imagwera mumadzi ozizira omwe ali mu chipangizocho, ndikuyika simenti mwachangu kukhala ufa wa amalgam. Pachikhalidwe chapamwamba champhamvu cha atomization chamadzi popereka ufa wachitsulo, ufa wachitsulo ukhoza kusonkhanitsidwa nthawi zonse, komabe ufa wochepa wachitsulo udzatayika ndi madzi atomu. Kwa atomization yamadzi othamanga kwambiri, chinthu cha atomized chimadzaza mu chipangizo cha atomization, chofulumizitsa, chosefedwa, (ngati n'kofunikira, icho chikhoza kuuma, kawirikawiri chimatumizidwa mwachindunji kuchokera ku dongosolo lotsatira.) palibe kuperewera kwa ufa wa amalgam pa nthawi yonseyi. Kwa atomization yamadzi othamanga kwambiri, chinthu cha atomized chimadzaza mu chipangizo cha atomization, chofulumira, chosefedwa, (ngati n'kofunikira, icho chikhoza kuuma, kawirikawiri chimatumizidwa mwachindunji kuchokera ku dongosolo lotsatira.) palibe kuperewera kwa ufa wa amalgam pa nthawi yonseyi. Kwa atomization yamadzi othamanga kwambiri, chinthu cha atomized chimadzaza mu chipangizo cha atomization, chofulumira, chosefedwa, (ngati n'kofunikira, icho chikhoza kuuma, kawirikawiri chimatumizidwa mwachindunji kuchokera ku dongosolo lotsatira.) palibe kuchepa kwa ufa wa amalgam m'nyengo yonse.

Kukonzekera kwathunthu kwazitsulo zazitsulo zazitsulo za ufa wa atomization zimakhala ndi zigawo zotsatirazi: Gawo losungunuka: Mutha kusankha ng'anjo yapakatikati yosungunula zitsulo kapena ng'anjo yosungunula yachitsulo yothamanga kwambiri. Mphamvu ya ng'anjo imadalira kuchuluka kwa ufa wachitsulo. Mukhoza kusankha ng'anjo yolemera makilogalamu 50 kapena ng'anjo yolemera makilogalamu 20. Gawo la Atomization: Gawo ili la zidazo ndi zida zosagwiritsidwa ntchito, zomwe ziyenera kupangidwa ndikukonzedwa molingana ndi malo omwe amapanga, makamaka kuphatikizapo tundish: pamene tundish imapangidwa m'nyengo yozizira, iyenera kutenthedwa; Atomizer: Atomizer imakhudza madzi othamanga kwambiri kuchokera pampopi yamadzi yothamanga kwambiri pa liwiro lodziwikiratu ndi ngodya motsutsana ndi madzi agolide ochokera ku tundish, kuwaphwanya kukhala madontho achitsulo. Pansi pa mphamvu ya mpope yomweyi, kuchuluka kwa ufa wabwino wachitsulo pambuyo pa atomization kumakhudzana ndi mphamvu ya atomization ya atomizer; atomization cylinder: ndi malo omwe ufa wa alloy umapangidwira, wophwanyidwa, utakhazikika ndikusonkhanitsidwa. Pofuna kupewa superfine aloyi ufa kutayika ndi madzi, ndi aloyi ufa wokonzeka ayenera kuloledwa kuima kwa nthawi pambuyo atomization pulverizing, ndiyeno kuikidwa mu bokosi kulandira ufa. Gawo la post-processing: bokosi lotolera ufa: lomwe limagwiritsidwa ntchito kusonkhanitsa ufa wa atomu, kulekanitsa ndi kuchotsa madzi ochulukirapo; kuyanika ng'anjo: kuyanika chonyowa aloyi ufa ndi madzi; makina owonera: kuwunika ufa wa alloy, ufa wochuluka wa alloy womwe sugwirizana ndi zomwe ukunena ukhoza kugwiritsidwa ntchito ngati zinthu zosungunulira kuti zisungunukenso ndi kusungunuka.

The Ultra-high pressure zitsulo ufa madzi atomization zida ali ndi makhalidwe awa

1-Itha kugwiritsidwa ntchito pazitsulo zambiri ndi ufa wophatikizika, ndipo mtengo wopanga ndiwotsika.

2-Ikhoza kukonzekera ufa wa subspherical kapena ufa waposachedwa.

3-Chifukwa chakumanga simenti mwachangu komanso osadzipatula, ma ufa amtundu wa amalgam amatha kukhala okonzeka.

4-Kukula kwa molekyulu ya ufa kumatha kufika pamalo oyenera posintha dongosolo loyenera.

Amapereka khalidwe zitsulo kuponyera

Kuti mudziwe zambiri chonde

Titumizireni Imelo :-info@hasungmachinery.com sales@hasungmachinery.com

Webusayiti: - www.hasungcasting.comhttps://hasungmachinery.com/

Nthawi yotumiza: Jun-30-2022