Makina Opitilira Kuponya

Mfundo yogwira ntchito ya makina opopera osalekeza amtundu wamba amatengera malingaliro ofanana ndi makina athu oponyera vacuum. M'malo modzaza zinthu zamadzimadzi mu botolo mutha kupanga / kujambula pepala, waya, ndodo, kapena chubu pogwiritsa ntchito nkhungu ya graphite. Zonsezi zimachitika popanda thovu lililonse la mpweya kapena kuchepa kwa porosity. Makina oponyera vacuum ndi apamwamba opitilira muyeso amagwiritsidwa ntchito popanga mawaya apamwamba kwambiri monga mawaya omangira, semiconductor, gawo lazamlengalenga.

-

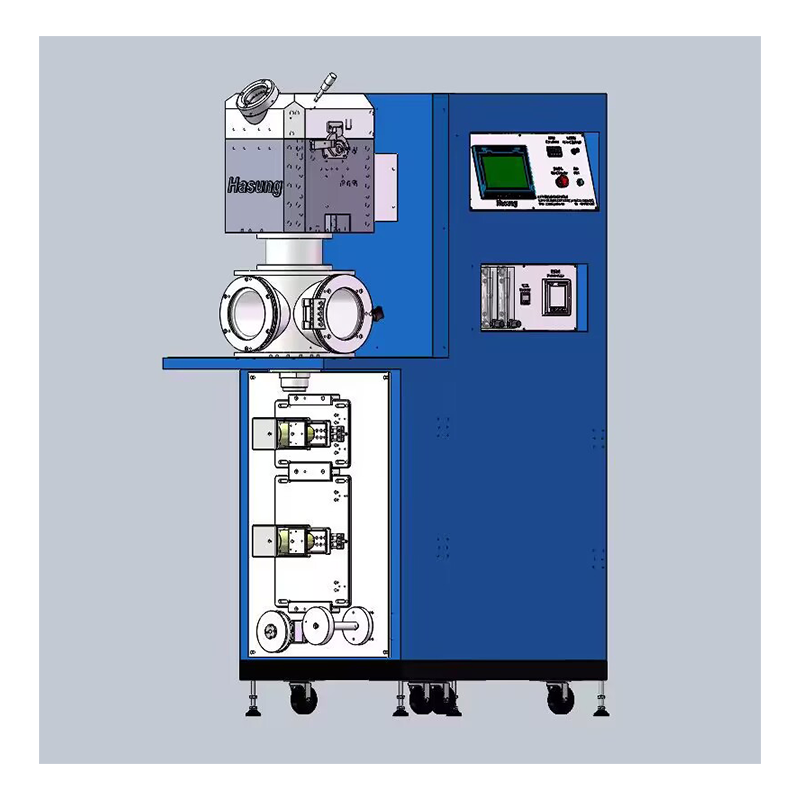

Zida za Hasung-High Vacuum Zopitirizabe Kuponya Pazitsulo Zamtengo Wapatali

Zitsulo zogwiritsidwa ntchito:zipangizo zitsulo monga golide, K golide, siliva, mkuwa, ndi aloyi awo

Makampani ogwiritsira ntchito:kulumikiza zida zamawaya, zodzikongoletsera, kukonza zitsulo zamtengo wapatali, ma labotale aku yunivesite ndi magawo ena okhudzana

Ubwino wazinthu:

1. Mpweya wapamwamba kwambiri (6.67 × 10-3pa), kusungunuka kwa vacuum, kusungunuka kwa mankhwala, mpweya wochepa wa okosijeni, wopanda pores, woyenera kupanga waya wapamwamba kwambiri;

2. Anti oxidation, inert gasi chitetezo kuyenga, kuthetsa vuto la aloyi makutidwe ndi okosijeni;

3. Uniform mtundu, ma elekitiromagineti ndi thupi yosonkhezera njira kupanga aloyi mtundu yunifolomu;

4. Chotsirizidwacho chimakhala ndi malo osalala ndipo chimagwiritsa ntchito kukoka pansi. Gudumu loyendetsa lachitidwa chithandizo chapadera, ndipo chotsirizidwacho sichimawonongeka pamwamba ndi pamwamba;

5. Kuwongolera kolondola kwa kutentha ± 1 ℃, pogwiritsa ntchito mita yowongolera kutentha kunja ndi dongosolo lanzeru la PID lowongolera kutentha, ndi kusiyana kwa kutentha kwa ± 1 ℃;

6. 7-inch full color touch screen, yosavuta kuwona / kukhudza, dongosolo latsopano, mawonekedwe a UI osavuta, osavuta kugwiritsa ntchito ndi kukhudza kumodzi kokha;

7. Chitetezo chambiri, chitetezo chambiri, kugwiritsa ntchito nkhawa kwaulere

-

Zitsulo Zamtengo Wapatali Wopingasa Vacuum Yopitilira Kuponya Makina

Horizontal vakuyumu mosalekeza kuponyera makina Ubwino

1. Sinthani khalidwe la mankhwala

2. Kuwongolera ndondomeko

3. Kuchulukirachulukira

4. Kugwiritsa ntchito mphamvu zamagetsi

Makhalidwe a yopingasa vacuum mosalekeza kuponyera makina

1. Chopingasa Kuponya Kapangidwe

2. Chipinda cha Vacuum

3. Kuzizira dongosolo

4. Makinawa ndi dongosolo lowongolera

5. Kusungunuka kwakukulu

6. Good kuponyera mankhwala

-

Mopitiriza Kuponya Machine kwa Gold Silver Copper Aloyi 20kg 30kg 50kg 100kg

1.Mwamsanga pamene siliva golide Mzere waya chubu ndodomosalekeza kuponya makinachifukwa zodzikongoletsera anapezerapo pa msika, izo analandira ndemanga zabwino kuchokera kwa makasitomala ambiri, amene ananena kuti mtundu uwu wa mankhwala akhoza bwino kuthetsa zosowa zawo.

2.Continuous Casting Machine Pakupanga Rod Strip Pipe yokhala ndi 20kg 30kg 50kg 100kg poyerekeza ndi zinthu zofanana pamsika, ili ndi zabwino zosayerekezeka pakuchita, mawonekedwe, mawonekedwe, ndi zina zambiri, ndipo imakhala ndi mbiri yabwino pamsika.Hasung kufotokoza mwachidule zolakwika za zinthu zakale, ndikuziwongolera mosalekeza. Mafotokozedwe a Makina Opitilira Kuponya Pakupanga Chitoliro Cha Ndodo yokhala ndi 20kg 30kg 50kg 100kg zitha kusinthidwa malinga ndi zosowa zanu.

-

Makina Oponyera Apamwamba Osasunthika A Zida Zatsopano Zomangirira Waya Wagolide Wamkuwa

Kuponyera zipangizo zamagetsi monga chomangira aloyi siliva waya wamkuwa ndi mkulu-chiyero wapadera waya Mapangidwe a dongosolo zipangizozi zimachokera pa zosowa zenizeni za polojekiti ndi ndondomeko, ndipo amagwiritsa ntchito mokwanira zamakono zamakono zamakono zamakono.

1. Landirani ukadaulo waku Germany wotentha kwambiri, kutsata pafupipafupi komanso ukadaulo wambiri woteteza, womwe ungasungunuke kwakanthawi kochepa, kupulumutsa mphamvu ndikugwira ntchito bwino.

2. Mtundu wotsekedwa + chipinda chosungunuka chotetezera gasi chingalepheretse makutidwe ndi okosijeni a zipangizo zosungunuka ndi kusakaniza zonyansa. Chida ichi ndi choyenera kuponyera zida zachitsulo zoyera kwambiri kapena zitsulo zoyambira zokhala ndi oxidized.

3. Gwiritsani ntchito mpweya wotsekedwa + wotsekera kuti muteteze chipinda chosungunuka. Mukasungunuka m'malo opangira mpweya, kutayika kwa okosijeni kwa nkhungu ya kaboni kumakhala kocheperako.

4. Ndi ntchito ya electromagnetic kusonkhezera + makina oyendetsa pansi pa chitetezo cha mpweya wa inert, palibe tsankho mu mtundu.

5. Pogwiritsa ntchito Mistake Proofing (anti- fool) yodzilamulira yokha, ntchitoyi ndi yabwino kwambiri.

6. Pogwiritsa ntchito dongosolo la kutentha kwa PID, kutentha kumakhala kolondola (± 1 ° C).

7. HVCC mndandanda mkulu vakuyumu mosalekeza kuponyera zida ndi paokha anayamba ndi kupanga, ndi luso patsogolo, ntchito mosalekeza kuponyera mkulu chiyero golide, siliva, mkuwa ndi kasakaniza wazitsulo zina.

8. Chipangizochi chimagwiritsa ntchito makina olamulira a Mitsubishi PLC, SMC pneumatic ndi Panasonic servo motor drive ndi zigawo zina zapakhomo ndi zakunja.

9. Kusungunula mu chipinda chotsekedwa + chotetezera gasi chosungunuka, kudyetsa kawiri, kusonkhezera kwa electromagnetic, kusonkhezera makina, firiji, kotero kuti mankhwalawa ali ndi makhalidwe opanda oxidation, kutayika kochepa, kopanda porosity, palibe tsankho mu mtundu, ndi maonekedwe okongola.

10. Mtundu wa Vacuum: Vuto lalikulu.

-

Vacuum Continuous Casting Machine ya Gold Silver Copper Alloy

Wapadera vacuum mosalekeza kuponyera

Kwa zinthu zomalizidwa bwino kwambiri:

Kuti tichepetse chiopsezo cha okosijeni panthawi yosungunuka komanso pojambula, timaganizira kwambiri kupewa kukhudzana ndi okosijeni komanso kuchepetsa kutentha kwazitsulo zokoka.

Zomwe zimalepheretsa kukhudzana ndi oxygen:

1. Dongosolo la gasi la inert la chipinda chosungunuka

2. Makina opumulira a chipinda chosungunula - chopezeka mwapadera pamakina a Hasung vacuum mosalekeza (VCC mndandanda)

3. Kuthamangitsa gasi pakufa

4. Kuyeza kutentha kwa kufa

5. Njira yowonjezera yachiwiri yozizira

6. Miyezo yonseyi ndi yabwino makamaka kwa ma aloyi okhala ndi mkuwa monga golide wofiira kapena siliva chifukwa zinthuzi zimakonda kutulutsa okosijeni mosavuta.Kujambula ndi momwe zinthu zilili zitha kuwonedwa mosavuta poyang'ana mawindo.

Madigiri vacuum akhoza kukhala malinga ndi pempho la makasitomala.

-

Makina Opitilira Kuponya a Gold Silver Copper Alloy

Mapangidwe a dongosolo la zipangizozi amachokera pa zosowa zenizeni za polojekiti ndi ndondomeko, pogwiritsa ntchito zipangizo zamakono zamakono.

1. Pogwiritsa ntchito luso lamakono la ku Germany lotentha kwambiri, kufufuza pafupipafupi komanso njira zamakono zotetezera, zimatha kusungunuka m'kanthawi kochepa, kupulumutsa mphamvu ndi kuteteza chilengedwe, komanso kugwira ntchito mwakhama.

2. Mtundu wotsekedwa + chipinda chosungunuka chotetezera gasi chingalepheretse makutidwe ndi okosijeni a zipangizo zosungunuka ndikuletsa kusakanikirana kwa zonyansa. Chida ichi ndi choyenera kuponyera zida zachitsulo zoyera kwambiri kapena zitsulo zoyambira zokhala ndi oxidized.

3. Pogwiritsa ntchito chipinda chotsekedwa + chotetezera gasi chosungunuka, kusungunula ndi kupukuta kumachitika nthawi imodzi, nthawiyo imakhala ndi theka, ndipo kupanga bwino kumakhala bwino kwambiri.

4. Kusungunuka m'malo a mpweya wa inert, kutayika kwa okosijeni kwa carbon crucible kumakhala kochepa.

5. Ndi ntchito ya electromagnetic yoyendetsa pansi pa chitetezo cha mpweya wa inert, palibe tsankho mumtundu.

6. Imatengera Mistake Proofing (anti- fool) yodzilamulira yokha, yomwe ndi yosavuta kugwiritsa ntchito.

7. Pogwiritsa ntchito dongosolo la kutentha kwa PID, kutentha kumakhala kolondola (± 1 ° C). The HS-CC mndandanda mosalekeza zida kuponyera amapangidwa paokha ndipo chopangidwa ndi luso lapamwamba ndipo anadzipereka kwa kusungunuka ndi kuponyera golide, siliva, mkuwa ndi kasakaniza wazitsulo n'kupanga, ndodo, mapepala, mapaipi, etc.

8. Zida izi zimagwiritsa ntchito Mitsubishi PLC pulogalamu yolamulira dongosolo, SMC pneumatic ndi Panasonic servo motor drive ndi zigawo zina zodziwika bwino zamtundu kunyumba ndi kunja.

9. Kusungunula, kugwedeza kwamagetsi, ndi firiji mu chipinda chotsekedwa chotsekedwa + chotetezera gasi, kotero kuti mankhwalawa ali ndi makhalidwe opanda oxidation, kutayika kochepa, kopanda pores, kopanda tsankho mu mtundu, ndi maonekedwe okongola.

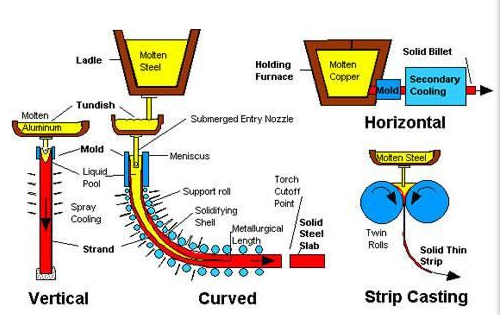

Kodi kuponyera mosalekeza ndi chiyani, ndi chiyani, ubwino wake ndi wotani?

Kuponyedwa kosalekeza ndi njira yabwino kwambiri yopangira zinthu zomwe zatha monga mipiringidzo, mbiri, slabs, mizere ndi machubu opangidwa kuchokera ku golide, siliva ndi zitsulo zopanda chitsulo monga mkuwa, aluminiyamu ndi alloys.

Ngakhale pali njira zosiyanasiyana zoponyera mosalekeza, palibe kusiyana kwakukulu pakuponya golidi, siliva, mkuwa kapena aloyi. Kusiyana kofunikira ndi kutentha kwa mpweya komwe kumayambira pafupifupi 1000 ° C ngati siliva kapena mkuwa mpaka 1100 ° C ngati golide kapena ma aloyi ena. Chitsulo chosungunuka chimaponyedwa mosalekeza mu chotengera chosungira chomwe chimatchedwa ladle ndipo chimayenda kuchokera pamenepo kupita ku nkhungu yoyima kapena yopingasa yokhala ndi mapeto otseguka. Pamene akuyenda mu nkhungu, amene utakhazikika ndi crystallizer, madzi misa amatenga mbiri nkhungu, amayamba kulimba pamwamba pake ndi kusiya nkhungu mu theka-olimba chingwe. Panthawi imodzimodziyo, kusungunula kwatsopano kumaperekedwa nthawi zonse ku nkhungu pa mlingo womwewo kuti ukhalebe ndi chingwe cholimba chosiya nkhungu. Chingwecho chimaziziritsidwanso ndi makina opopera madzi. Kupyolera mu ntchito kwambiri kuzirala n'zotheka kuonjezera liwiro crystallization ndi kupanga mu chingwe homogeneous, zabwino grained dongosolo kupereka theka-anamaliza mankhwala katundu wabwino zamakono. Kenako chingwe cholimbacho chimawongoleredwa ndikudulidwa mpaka kutalika kwake ndi kameta kapena tochi yodulira.

Magawowa atha kugwiritsidwanso ntchito pazotsatira zogubuduza pamzere kuti apeze mipiringidzo, ndodo, ma billets otulutsa (zopanda kanthu), ma slabs kapena zinthu zina zomalizidwa mosiyanasiyana.

Mbiri yakuponya mosalekeza

Kuyesera koyamba kuponya zitsulo mosalekeza kunachitika pakati pa zaka za m'ma 1800. M'chaka cha 1857, Sir Henry Bessemer (1813-1898) adalandira chilolezo choponya zitsulo pakati pa ma roller awiri ozungulira kuti apange zitsulo. Koma nthawi imeneyo njira imeneyi inalibe tcheru. Kupita patsogolo kotsimikizika kudapangidwa kuyambira 1930 kupita mtsogolo ndi njira ya Junghans-Rossi yopitilira kutulutsa kwazitsulo zopepuka komanso zolemera. Pankhani ya chitsulo, njira yopitilira yoponyera idapangidwa mu 1950, (komanso pambuyo pake) chitsulocho chidatsanulidwa mu nkhungu yokhazikika kuti ipange 'ingots'.

Kuponyedwa kosalekeza kwa ndodo yopanda chitsulo kunapangidwa ndi ndondomeko ya Properzi, yopangidwa ndi Ilario Properzi (1897-1976), yemwe anayambitsa kampani ya Continuus-Properzi.

Ubwino wa kuponyera mosalekeza

Kuponyera mosalekeza ndi njira yabwino kwambiri yopangira zinthu zomwe zamalizidwa pang'ono zazitali zazitali ndipo zimapangitsa kuti pakhale zochulukirapo pakanthawi kochepa. Ma microstructure azinthu ndi ofanana. Poyerekeza ndi kuponyera mu nkhungu, kuponyera mosalekeza kumakhala kopanda chuma pakugwiritsa ntchito mphamvu komanso kumachepetsa zinyalala zochepa. Komanso, katundu wa mankhwala akhoza kusinthidwa mosavuta ndi kusintha magawo akuponya. Popeza ntchito zonse zitha kupangidwa zokha ndikuwongoleredwa, kutulutsa kosalekeza kumapereka mwayi wambiri wosinthira kupanga mosavuta komanso mwachangu kuti zisinthe zomwe msika ukufunikira ndikuphatikiza ndi ukadaulo wa digito (Industrie 4.0).